Magnets, Force and Trust: Designing Invisible Structure

Magnets introduce a different responsibility.

Until now, joins were tested through form, material and weight. Magnets shifted the focus to active force. Unlike screws or bolts, magnetic connections are invisible and conditional. They rely on alignment and balance rather than visible confirmation.

This stage examined what it means to design a join that holds without being seen.

Why Magnets?

Magnets were not a novelty. They allow repeated assembly and disassembly without damaging material or relying on permanent fixings. They align with the project’s interest in reversibility and reconfiguration.

But magnets are unforgiving. Precision is not optional.

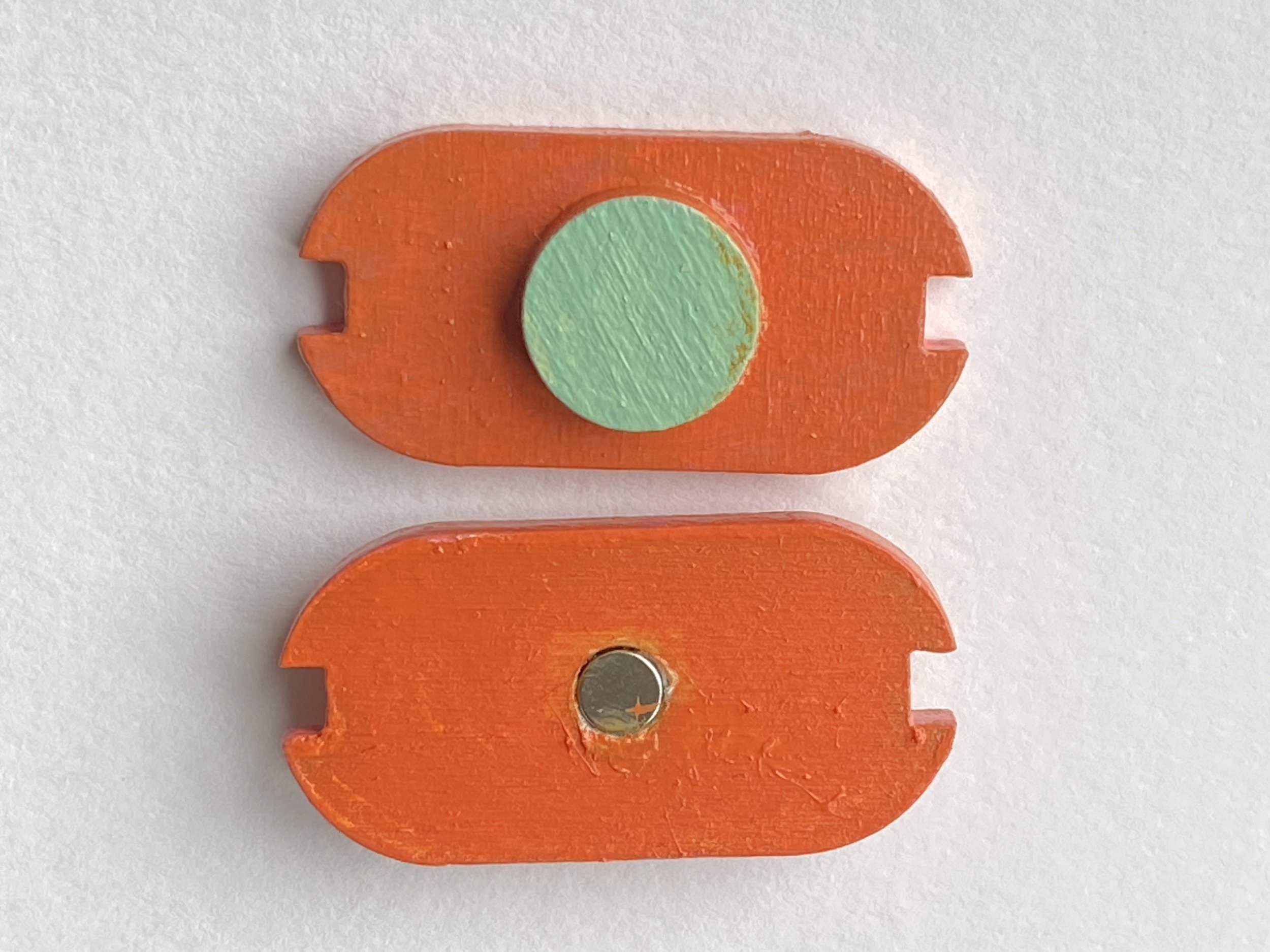

Magnetic join system prototypes.

Embedding Force

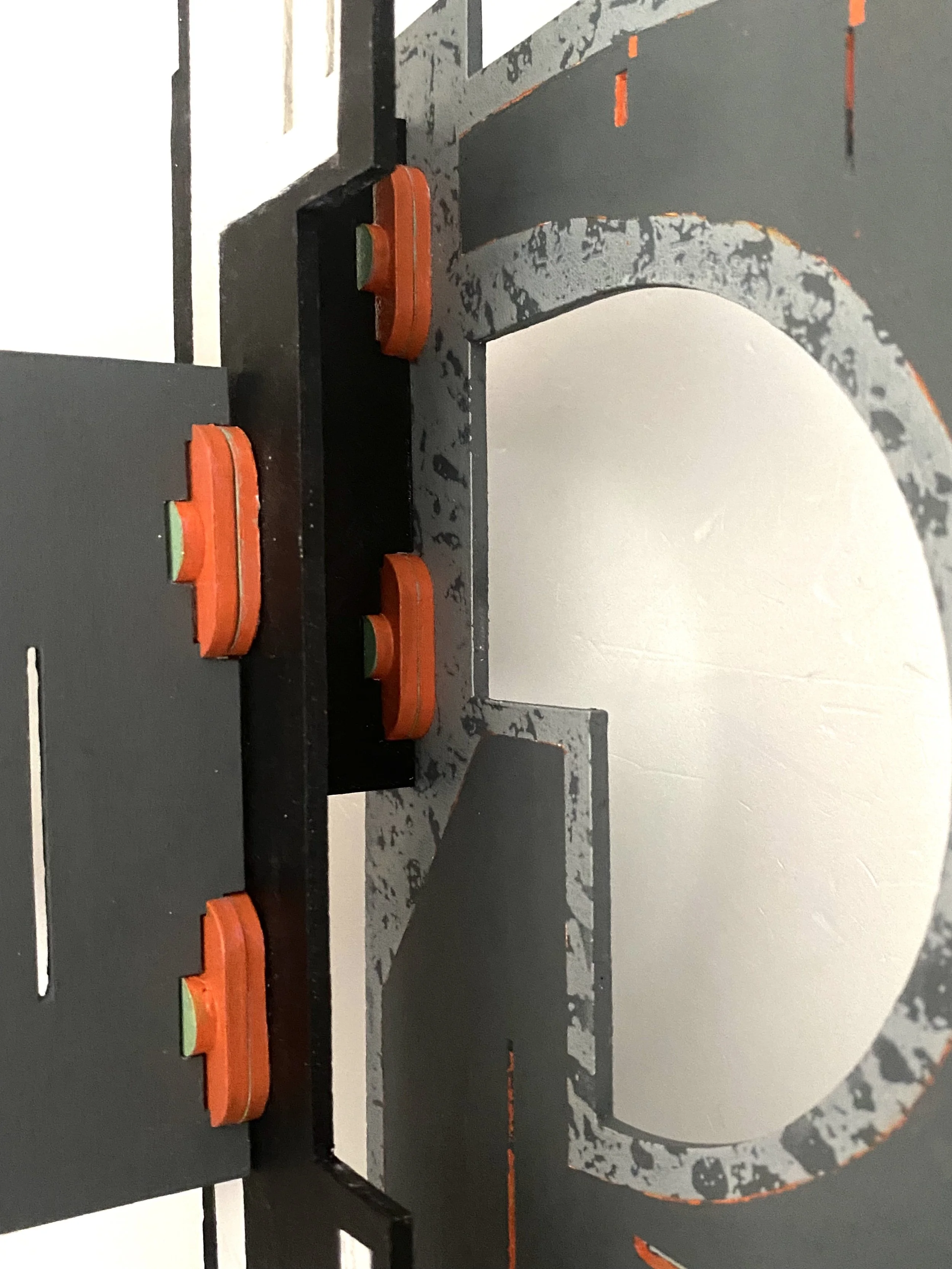

Embedding magnets required careful control of position, depth and orientation. Small inconsistencies caused failure — repulsion instead of attraction, rotation instead of stability, or a join that appeared secure but failed under light load.

Magnetic joins cannot be retrofitted. They must be designed into the structure from the outset.

A tension also emerged between concealment and legibility. The magnet may be hidden, but its behaviour must be clear. A join that feels uncertain erodes confidence.

Magnetic join system tested in a sculpture design.

Testing and Failure

For early experiments, one join design was laser cut in wood and painted with enamel to test repeated assembly. Some configurations snapped into place with clarity. Others revealed subtle instability: slight shifts under load, uneven force distribution, gradual misalignment.

These failures were diagnostic. They exposed mismatched magnet strength, inadequate tolerance and geometric imbalance.

A join does not fail only when it breaks. It fails when it makes the user hesitate.

Trust as a Design Outcome

Trust became central. A magnetic join must communicate through behaviour. It should guide the hand, correct alignment and settle decisively.

Force became a design material alongside Jesmonite, concrete and silicone.

What This Stage Contributed

This stage clarified that:

magnetic joins demand structural restraint

alignment matters as much as strength

tolerance must be designed deliberately

trust is measurable through repeated handling

Repetition exposed patterns of success and failure that a single test could not.

Looking Ahead

With magnetic joins functioning reliably at small scale, the next challenge is expansion. Increased load, varied orientation and larger configurations introduce new pressures.

The project now moves toward testing force under greater weight — and toward new forms of failure, including material incompatibility and chemical reaction, where control is less certain.