Digital Drawing as Structural Thinking: From Archive to Magnetic Join

Digital Drawing as Structural Thinking

From Archive to Magnetic Join

By this stage, drawing was no longer speculative. Archival research, prototyping and material testing had already imposed constraints. Digital drawing became the place where those constraints were negotiated rather than imagined away.

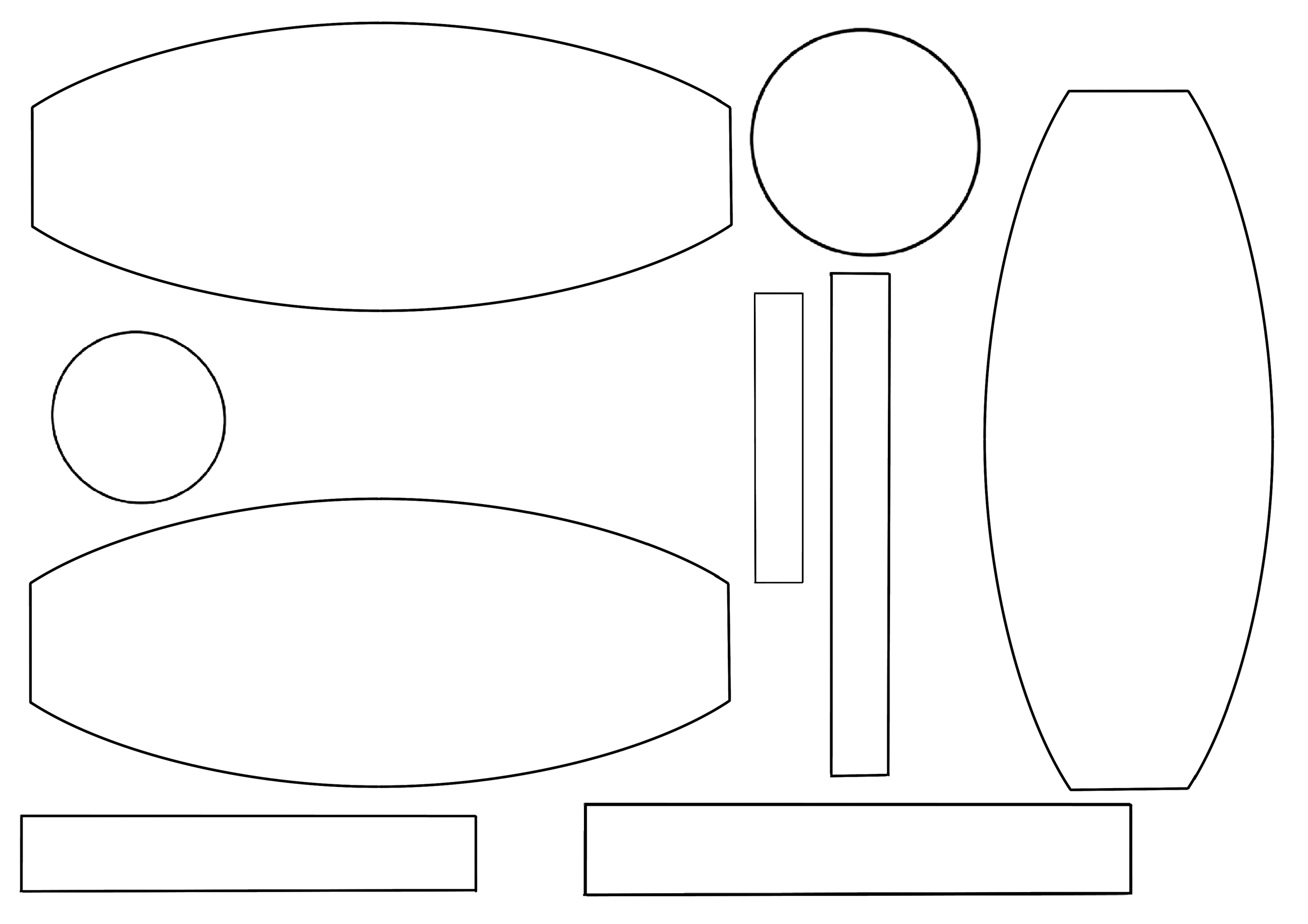

The aim was not to design finished objects, but to develop joinery systems capable of surviving translation into material reality.

Drawing as Problem-Solving

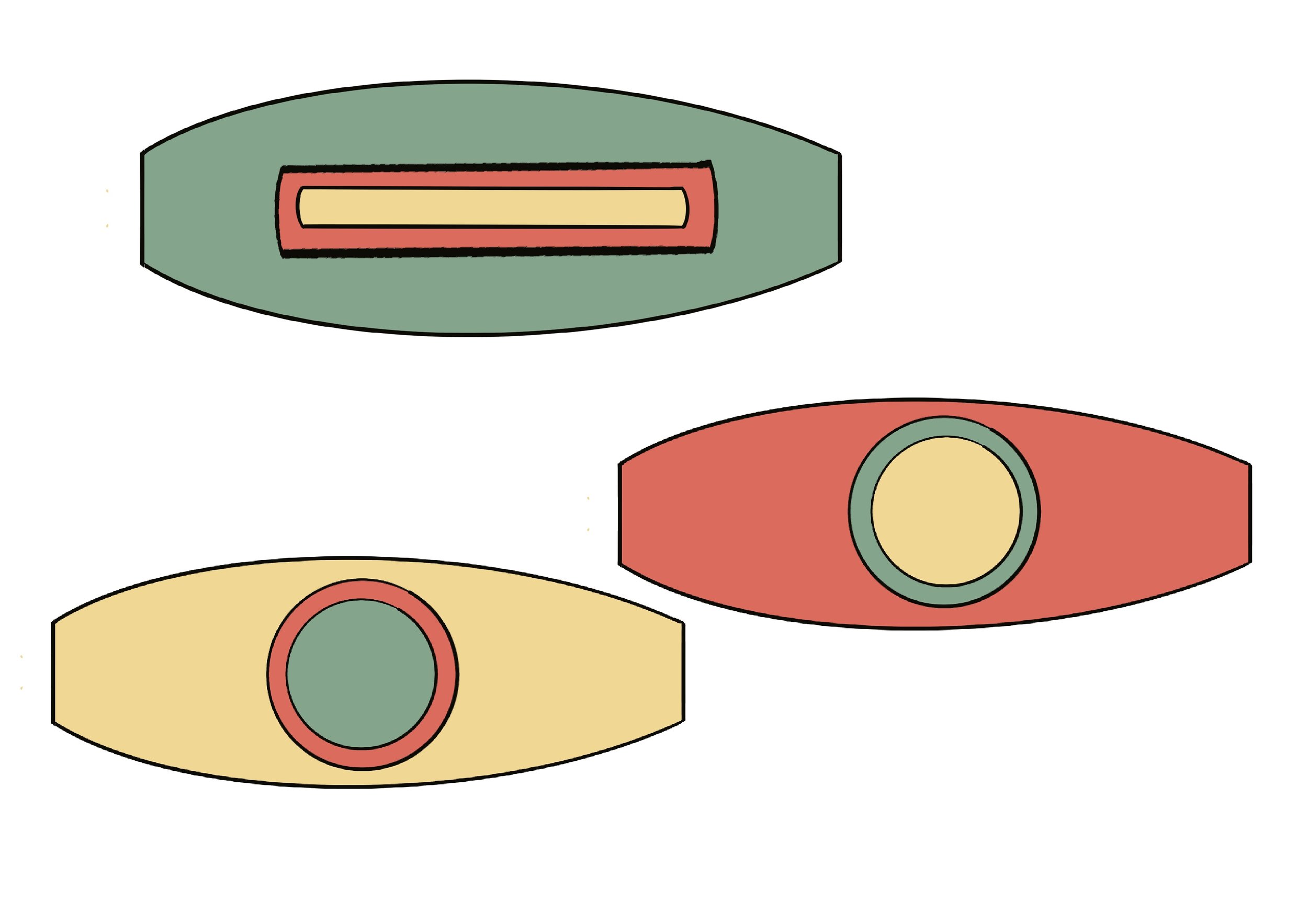

I use Procreate as a working sketchbook rather than a presentation tool. Its value lies in speed and repetition. At this stage, drawing was about testing force, alignment and proportion — not resolving surface.

Research into G-Plan, Ercol and E. Gomme informed the process, but not literally. I was not reproducing historic joints. I was extracting principles: managing stress, controlling movement, achieving clarity without excess.

These principles were abstracted and reworked within my own sculptural language.

From Furniture Logic to Sculptural Form

Furniture joinery resolves load, repetition and repair at human scale. My sculptures operate under different expectations — informed by architectural mass and spatial restraint — but they still depend on structure and legibility.

The drawings became a site of translation. Furniture logic was inserted into forms derived from architectural thinking. Some elements were exaggerated, others reduced. Certainty gave way to controlled ambiguity.

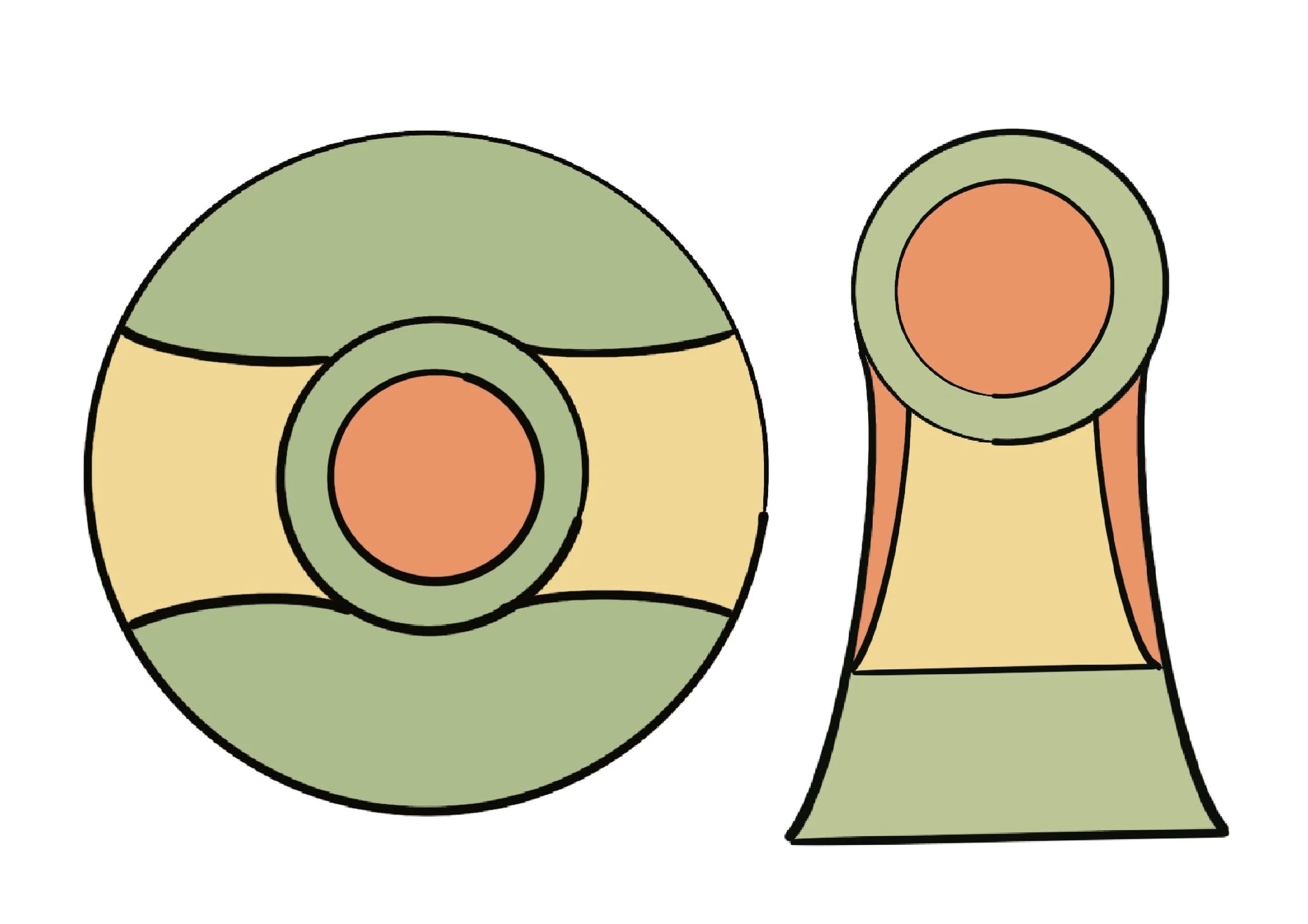

The introduction of magnets complicated this further. Magnetic joins demand precision but introduce invisible force. Alignment becomes critical, yet trust remains unstable. These conditions were embedded in the drawings from the outset.

Digital Translation and Constraint

When drawings moved from Procreate into Adobe Illustrator, ambiguity narrowed. Illustrator forces closure. Lines must resolve. Measurements must align. Preparing files for laser cutting exposed weaknesses immediately. Corners that looked solid became fragile. Negative space became structural risk.

Iteration was deliberate. Files were revised not to perfect them, but to locate their limits.

Designing for Failure

A shift occurred here: failure became part of the method. Some joins were drawn expecting them to fail. Their purpose was diagnostic — to expose stress points, magnet misalignment or structural weakness.

These iterations were not missteps. They produced information.

Drawing stopped being a search for solutions and became a way of refining the questions.

What Drawing Needed to Contain

By the end of this stage, a viable join drawing had to account for:

material thickness and weight

tolerance and misalignment

magnet placement and containment

assembly and disassembly by hand

visual clarity in use

If a drawing ignored these factors, it was discarded — no matter how convincing it appeared on screen.

What This Stage Establishes

This phase marked a move from open research into structured development. The drawings were tools for pressure-testing ideas before they entered material form.

By embedding weight, tolerance and failure into the drawing process, the project moved closer to joinery systems capable of operating at scale — holding architectural presence while retaining modular logic.

With digital designs prepared for testing, the next step was physical production: laser-cut multi-part components assembled into working prototypes.

That transition would determine how much the drawings could withstand contact with reality.