Laser Cutting, Tolerance and the Myth of Precision

When Drawings Meet Material

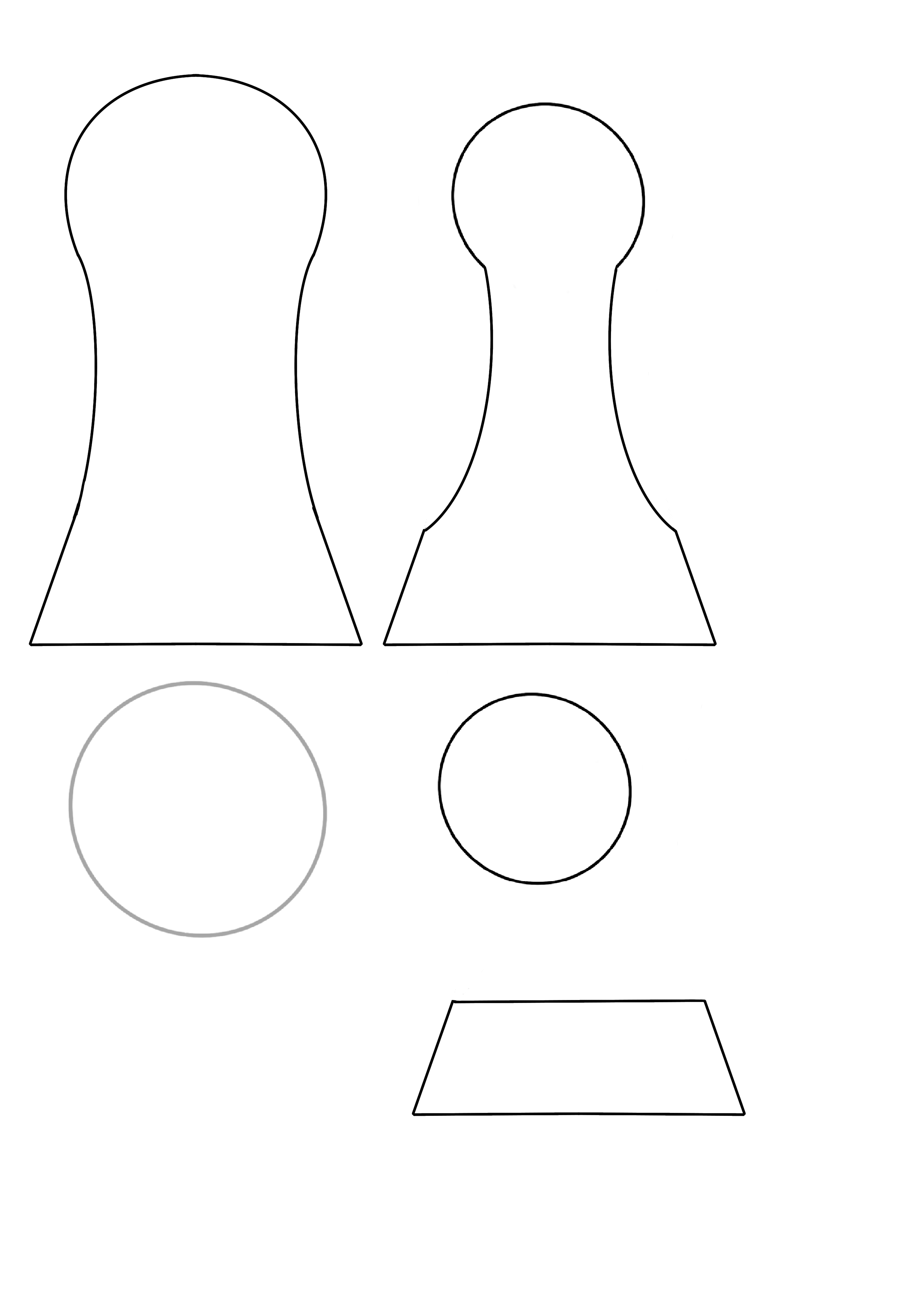

Digital drawings suggest certainty. Laser cutting removes it. This stage translated Illustrator join designs into laser-cut components, testing tolerance, alignment and assembly. What emerged was friction.

On screen, the joins appeared resolved. In material, they became conditional. Minor variations in thickness disrupted alignment. Kerf width altered dimensions enough to loosen tight fits. Corners that felt robust in vector form proved fragile once cut.

These were not mistakes. They were limits. Laser cutting offers repeatability — not absolute precision.

Assembly as a Test of Intelligence

Assembly exposed whether the joins were structurally coherent or merely visually convincing.

Some locked together as intended. Others resisted entirely, revealing geometric weaknesses that drawing had concealed.

Magnets intensified the problem. Magnetic force is intolerant of misalignment. A fraction of a millimetre could shift attraction into repulsion or introduce rotational instability.

It became clear that magnetic joins must be designed for failure as much as for connection.

Adjusting the System

Rather than correcting individual faults, I looked for patterns. Certain geometries consistently failed. Others absorbed variation and remained stable.

Files were revised to introduce tolerance rather than eliminate it. Clearances widened. Contact points simplified. Complexity was reduced. Some designs were abandoned.

This was refinement through subtraction.

Alongside magnetic joins, I began developing a nut-and-bolt system integrated into the laser-cut geometry. This was not a fallback. It introduced a different logic: visible compression rather than invisible force. Magnets rely on alignment and trust; bolts rely on tension and declaration. Testing both systems in parallel exposed contrasting forms of structural intelligence.

The Problem With Precision

Digital precision does not guarantee structural strength. Overly exact joins proved brittle, dependent on ideal conditions rarely met in practice.

By contrast, joins that allowed for slight movement and variation proved more resilient. They accommodated the realities of cutting, handling and repeated assembly without losing structural integrity. This understanding directly challenged earlier assumptions and reshaped the direction of subsequent designs. This ultimately led to the consideration of a nut and bolt system to explore alongside the magnetic system.

What This Stage Established

Laser cutting transformed drawing into measurable consequence.

It established:

tolerance as a design tool

magnet alignment as a structural vulnerability

resilience over false precision

simplicity as strength

the structural and conceptual contrast between magnetic and mechanical joining

Assembly became a point of evaluation, not a final step.

Setting Up the Next Phase

The outcomes of this stage made it clear that successful joinery could not be resolved through cutting alone. The next phase required a different level of control — one where surface, thickness and internal structure could be shaped more deliberately. This shifted the project toward mould-making and casting, where tolerance could be negotiated differently and joins could be tested under new conditions of weight and finish.

Laser cutting had done its job. It exposed the limits of digital certainty and forced the work to become materially honest.